Spray application is substituted by a small dot dispensed on each pad (sanitary napkin or towel). This method of dispensing eliminates the risk of perfume being atomized to the environment and ensures that every product receives a precise and equal dose, even during machine startup or at variable line speeds.

The perfume can be acknowledged as a hot-melt-like liquid, in which case it may be applied with slot coat applicator. In contrast, the substance’s formula may be oil based. In this case, a cold glue dispensing system would be best suited for the job. Spray application is not the most cost-effective option, as most of the perfume is dispensed into the air. To avoid wasting product, a precise bead application is better utilized. Because perfumes and lotions are highly corrosive, having the proper equipment fitted with ceramic seats and/or nylon and steel module bodies will most likely make a huge difference in regards to maintenance.

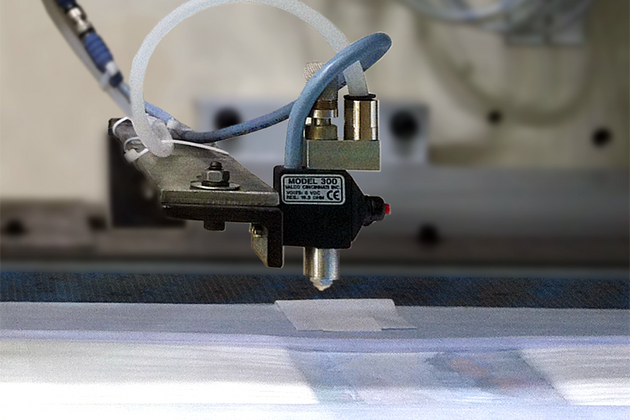

Perfume dispensing applicator