Decrease your material cost by 40% or more

Compared to double-sided pressure sensitive tapes, the SealTak system offers a more cost-effective and efficient sealing process by using pressure-sensitive adhesive and a release liner. Get these immediate benefits

Increase production and reduce downtime by eliminating the need for excessive tape roll changes

Reduce material costs–the cost of buying bulk adhesive and bulk silicone paper is far less than transfer tape

Produce a stronger bond by evenly depositing adhesive onto the substrate

Deferred-Use Packaging System – Turning Significant Profit .

Molten hot melt adhesive is evenly applied onto the substrate in ribbon, bead, or spray form during the converting process. The release liner is then deposited over the adhesive with an offset, which allows for the easy peel and seal feature that is not possible with transfer tape.

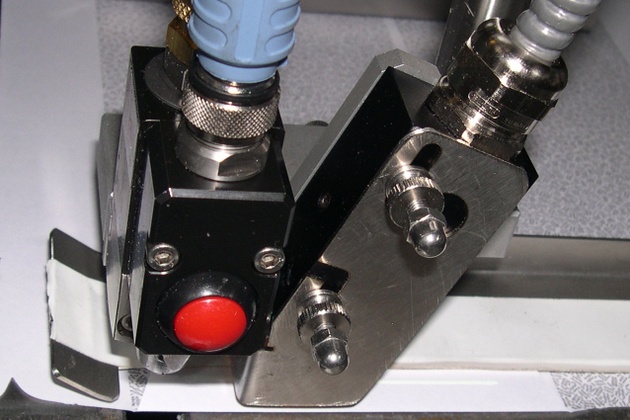

Release Liner Staging Unit – A Process Made Simple.

A release liner is fed through the “accumulator” to the liner’s applicator head and then deposited onto the adhesive just downstream from the gluing area. A process made simple with SealTak.

Side seam gumming