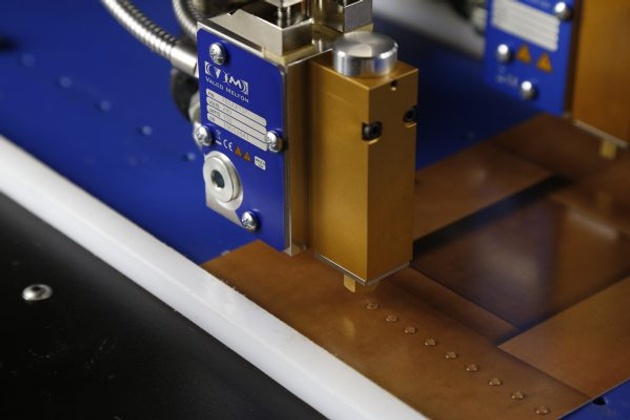

Valco Melton’s MXM electric hot melt valve is the workhorse for any hot melt dispensing solution. The MXM electric valve can operate at extremely high speeds reaching 15,000 cycles per minute for short bursts and have a lifetime capable of more than 2 billion cycles depending on operating conditions.

The MXM electric valve is used for many different applications, most notably in industry where production uptime is essential and adhesive savings ROI is paramount. Other applications including Folding Carton, Sift Proof Packaging and Slot Coat applications are ideal fits for the MXM as it has a variety of attachments that make it configurable to nearly any requirement. The MXM is widely known as the “EcoStitch” valve in Food and Beverage packaging where end users focus on adhesive usage reduction, instant ROI and process improvement.

The evolutionary MXM EcoStitch valve is not limited by viscosity or temperature and can fire as many 2 billion cycles before service may be required. The MXM is compatible with viscosities ranging up to 7,000cps and with operating temperatures up to 400 degrees F.

The MXM uses a custom electromagnetic coil design that maximizes speed, accuracy and consistency all while being able to run in EcoStitch mode and not have any performance reductions due to dynamic seal wear as found with all pneumatically operated gluing valves.