Valco Melton pioneered the use of warming hoses for tissue adhesives. Warming the adhesive through a specially designed, heated hose (not a traditional hot melt hose that can scorch the cold glues) eliminates the variable of viscosity changes due to ambient temperature fluctuations in the converting facilities or adhesive storage warehouses.

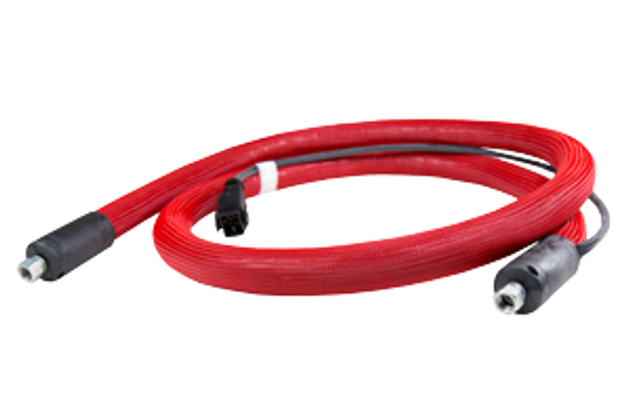

Foam insulation and an outer braided layer provides high thermal efficiency for the prevention of heat transfer caused by convection and to protect hose components.

Benefits of Valco Melton’s warming hoses also include assisting with better tack and overall adhesion and glue drying capabilities.