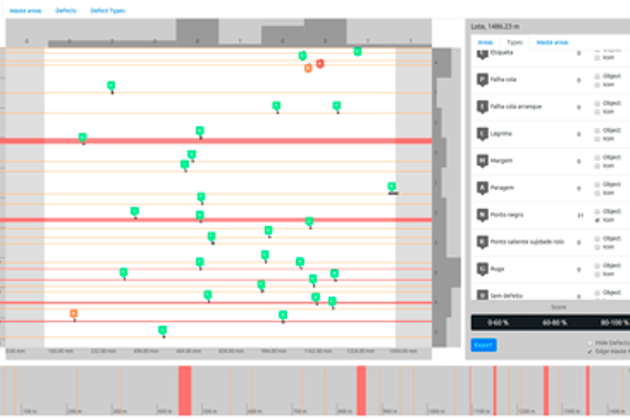

Valco Melton’s Coat-Inspekt offers real-time vision inspection for coating processes. An Artificial Intelligence system automatically classifies all errors detected into pre-set categories, facilitating an immediate and intutive overview of the production status. This, combined with the historical data stored in the system, brings in a powerful tool for process analysis.

• Improve customer satisfaction by guaranteeing a defect-free product. Coat-Inspekt detects any and all defects on the roll, allowing you to eliminate them in the following step of the process, which is commonly the slitting station.

• Minimize waste — Reduce cost. Real-time error detection allows your operators to take an immediate corrective response.

• Support your continual improvement actions. All defects are categorized by an artificial intelligence system, which provides you real-time insight on your production. These reports are stored for further analysis, and product traceability, allowing to take informed decisions to improve product quality and process efficency.